Seismic Gas Shutoff Valves

How do Seismic Gas Shut off valves work?

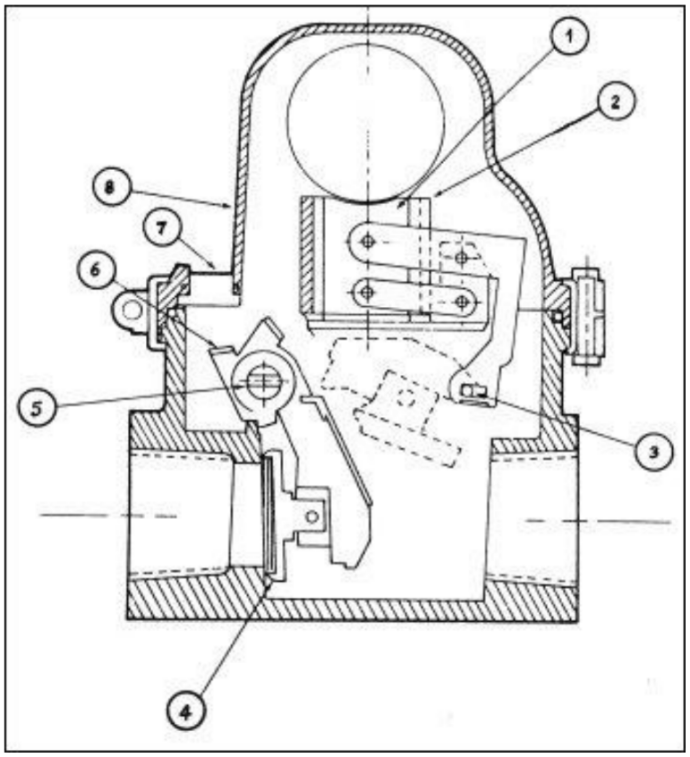

- The simple design consists of a swing check valve and an acceleration – sensitive triggering mechanism.

- The ball is located on a stationary post (item #1) with a seat formed of certain angularity to horizontal. During a violent earthquake, the ball moves & strikes the reacting cylinder (item 2), which causes the CALIFORNIA Valve to close.

- Note the rolling latch! The latch mechanism automatically resets when subjected to very low amplitude accelerations. The mechanism will not creep in time to an actuating mode.

- Stationary post, supporting ball

- Reacting cylinder

- Rolling latch (no sliding friction)

- Soft seat

- Manual reset

- Position indicator

- Window

- Bonnet

Why install Seismic Gas Shutoff Valves?

We live in New Zealand, earthquakes occur regularly, and we all know that one of the most significant risks with shocks is fire.

It does not need a significant earthquake to shake a gas pipe or gas equipment to the point where a joint is dislodged, causing a leak

with the potential to start a large fire. In an earthquake, a seismic gas valve will trigger closing the gas supply and minimising the gas escape.

Many insurance companies deem the risk significant and now require commercial and industrial clients to install seismic protection in the form of a gas seismic shut off known as a California valve.

So, in a nutshell –

- Protect your plant from gas explosion in the event of an earth quake

- Comply with insurance companies requirements

- Possibly lower your insurance costs

What is a California Valve?

CALIFORNIA Valves utilise a swing-check valve arrangement with an acceleration-sensitive triggering mechanism. The trip mechanism consists of a steel ball that rests on tapered cup-shaped support. The horizontal motions of an earthquake cause the ball to move from the centre of the support, which allows the ball’s mass to act upon the movable pipe of the trip mechanism to actuate the valve and initiate closure.

CALIFORNIA Valves do not use any source of internal or external electrical power. They remain closed until manually reset. These valves are mounted in the gas line upstream or downstream of the gas-line pressure regulator and gas meter outside the structure.

CALIFORNIA Valves do not replace manual shutoff valves installed in the gas service line. Springs assist in closing, and gas pressure helps in holding the disc in the closed position. The trip mechanism is factory set and sealed. A sight glass combined with an open/closed indicator that has green (i.e., open) and red (i.e., closed) bars enables the valve’s position to be easily and quickly determined.

How Flow Industries can help you.

As experienced industrial gasfitters we can help you advance the safety of your plant.

- We conduct site assessments and risk analysis

- We design solutions so you can be assured that you are safe in an extreme event.

- We supply install and test seismic shutoff valves

- Most importantly as certifying gas fitters AND practitioners approved by Worksafe for industrial gas, we have the necessary authority to certify industrial gas equipment

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.